TUBE FITTING PERFORMANCE CENTER

straightforward and transparent info to help you make INFORMED decisions

TUBE FITTING COMPATIBILITY TESTING

A COMMON QUESTION

we receive from potential customers considering our tube fittings is: ‘Are they compatible with the fittings I’m already using?’

The answer is a straightforward ‘YES’ but instead of pushing a sales pitch we’d rather just show you.

In the following test we MIXED our Superlok tube fittings with a well known legacy brand in as many ways as we could think of before testing at FULL bottle pressure of 2,500 psig while under water.

It doesn’t get much more transparent than this.

Follow along below:

testing summary:

The assembly was placed in a container which was subsequently filled with deionized water to cover the connections under test.

The Superlok needle valve (item 15) was connected to a fully pressurized bottle of Nitrogen as delivered by Airgas. Initial bottle pressure exceeded 2500 psig (172 bar) using a stainless braided hose.

The Superlok needle valve was opened introducing full bottle pressure to the assembly. The assembly pressure was confirmed using the digital gauge installed on the assembly.

While pressurized visual inspection was performed on all connections. Since the assembly was tested under water, any leaks would immediately produce bubbles rising to the surface of the water. A pass/fail determination was recorded.

The assembly was then vented and re-pressurized a second time to confirm the initial findings.

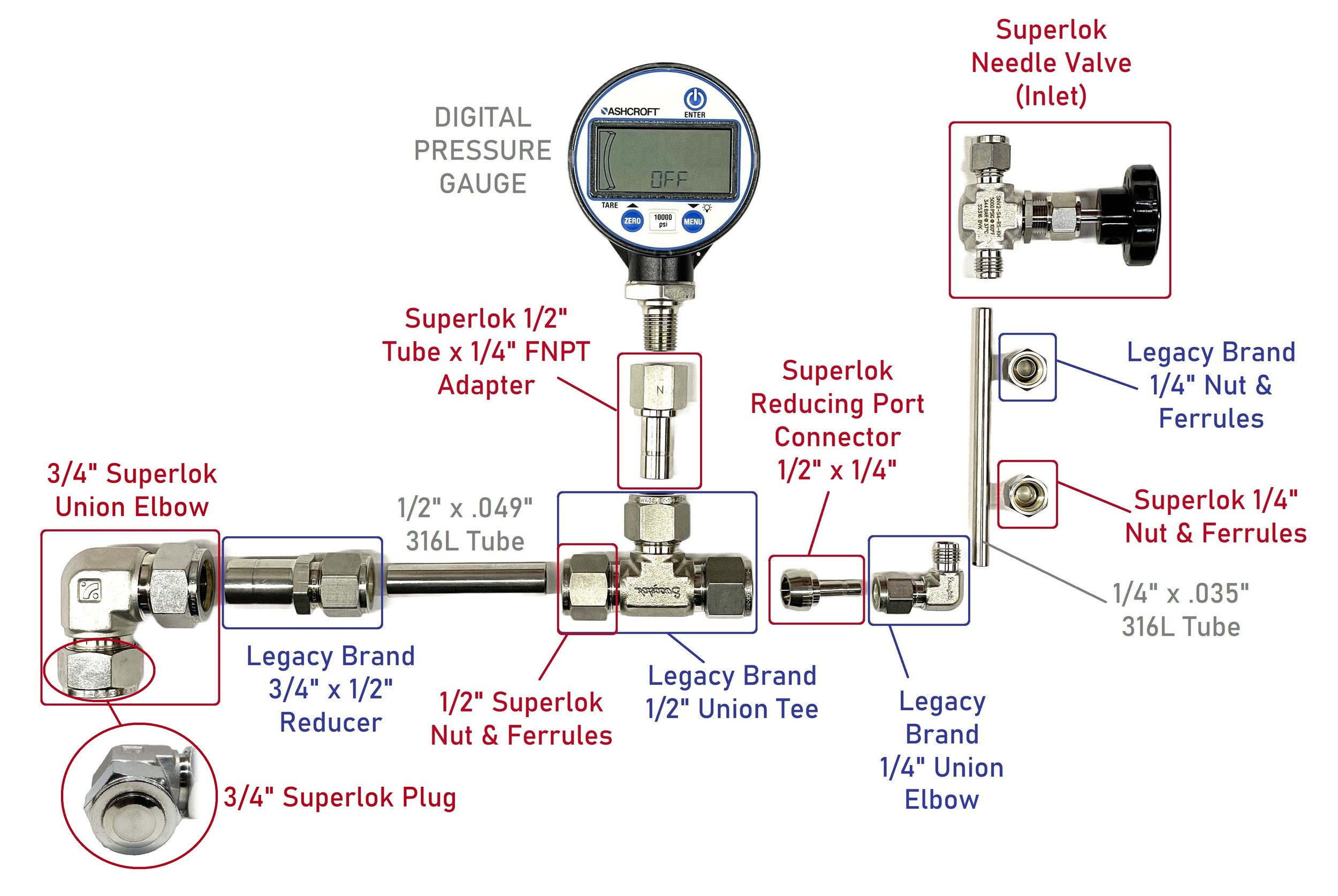

test 1 ASSEMBLY BILL OF MATERIALS

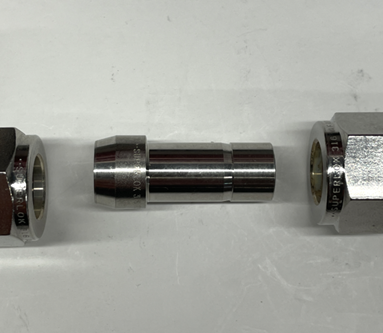

The completed assembly, made up of intermixed and interchanged two ferrule tube fittings as well as standard wall 1/4" and 1/2" annealed stainless tubing

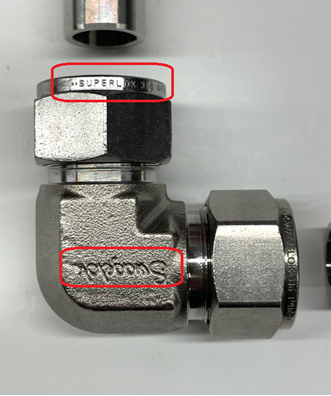

A 3/4" Superlok union elbow with a Superlok plug on the bottom port. In the right port, Superlok ferrules are swaged onto a Legacy Brand 3/4" x 1/2" reducer using the standard 1-1/4 turn procedure

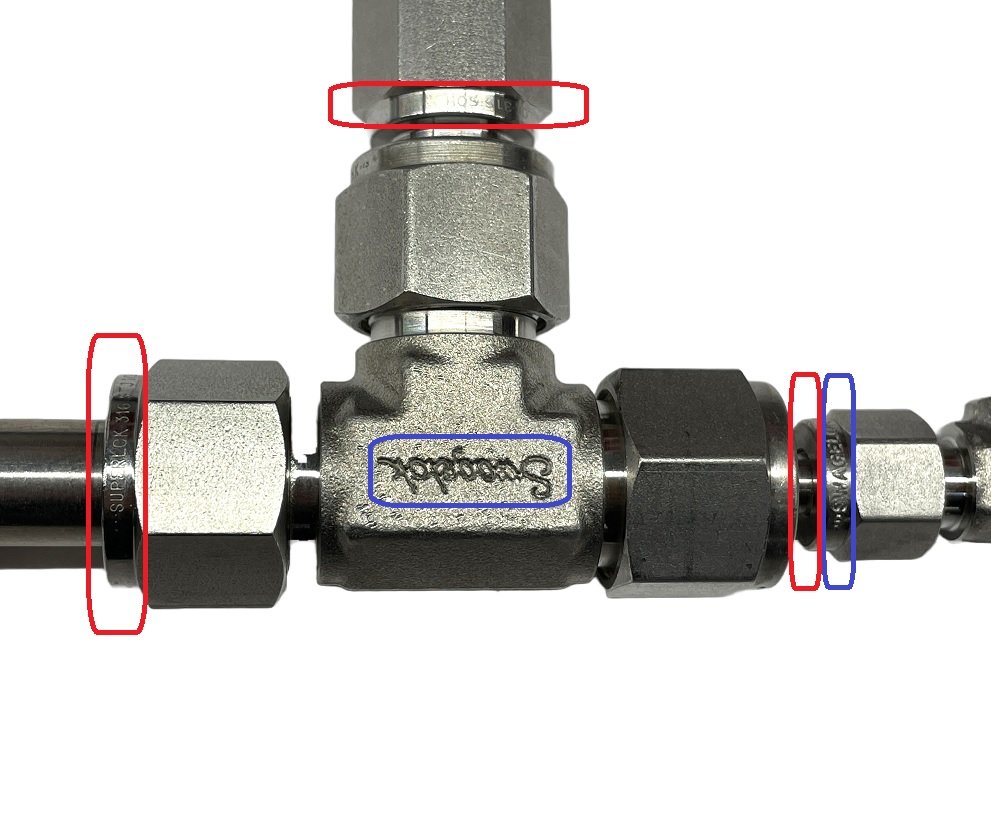

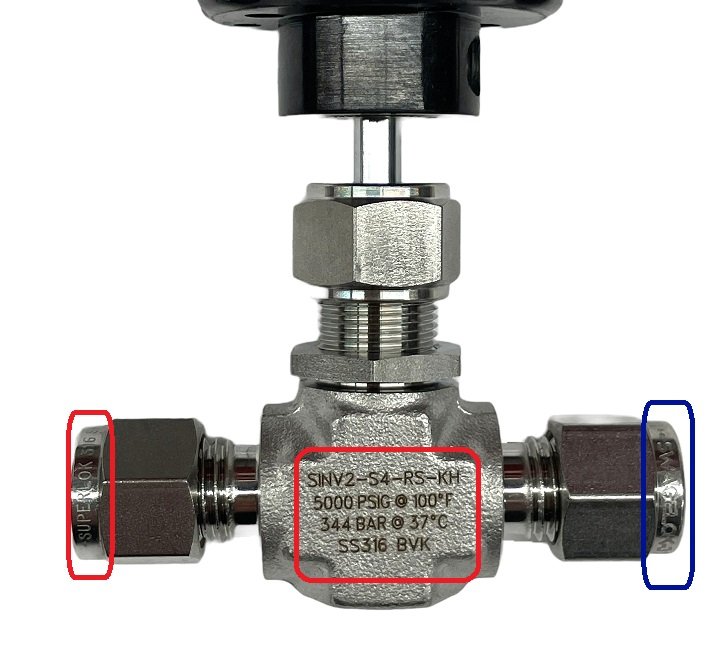

The left port of this Legacy Brand tee utilizes Superlok nut & ferrules creating an intermixed connection. The top port is swaging onto a Superlok FNPT tube adapter creating an interchanged connection. And the right port seals using a Superlok reducing port connector

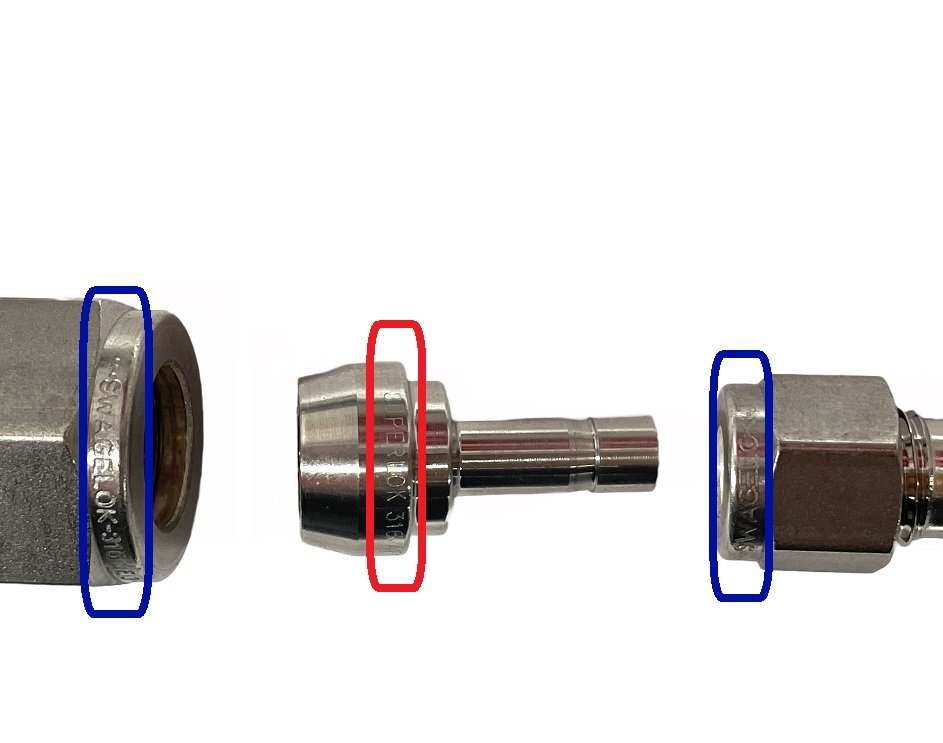

Here the ferrules on the Legacy Brand tee are discarded to accept the flared side of a 1/2" Superlok port connector. Opposite, a Legacy Brand 1/4" Union elbow is swaged onto the same 1/4" Superlok port connector

The nut & ferrules on the top port of this 1/4" union elbow were replaced with Superlok nut & ferrules creating an intermixed connection. On the left port a Superlok tube stub is swaged onto creating an interchanged connection.

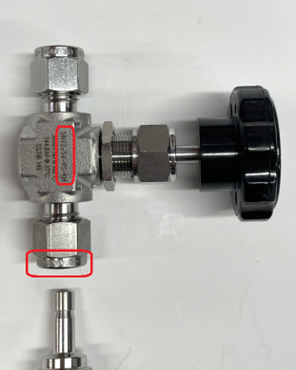

In the reverse scenario, the 1/4" nut & ferrules were replaced with Legacy Brand nut & ferrules on this Superlok needle valve creating another intermixed connection

WATCH TEST 1

OUR GOAL WAS TO CREATE A SIMPLE TEST THAT WAS EASY TO OBSERVE

TEST 2 ASSEMBLY BILL OF MATERIALS

The completed test assembly consisting of intermixed and interchanged 1/4", 1/2" and 3/4" tube fittings along with 1/4" and 1/2" stainless tubing

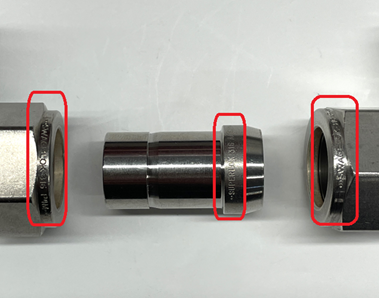

Item 1: Intermixed 1/4" legacy brand nut, 1/4” Superlok front ferrule, 1/4” Legacy brand rear ferrule utilized on a 1/4” Superlok cap.

Item 3: Intermixed 1/4" legacy brand nut, 1/4” Superlok rear ferrule, 1/4” legacy brand front ferrule. 1/2" legacy brand nut & ferrule set on a Superlok reducing union elbow body

Item 5: 3x 1/2” Superlok nut & ferrule sets on a 1/2" legacy brand union tee body to create interchanged connections

Item 6: 1/2” Superlok FNPT tube adapter installed into legacy brand union tee

Item 7: 1/2” Superlok port connector to make up an interchanged connection on legacy brand tee and a standard 1/2” Superlok connection on elbow

Item 8: 1/2” Superlok tube adapter elbow installed into 1/2" x 3/4" legacy brand reducer

Item 9: 3/4" x 1/2" legacy brand reducer with 1/2” Superlok nut & ferrules

Item 10: 3/4" legacy brand union elbow with one set of 3/4” Superlok nut & ferrules and a standard legacy brand connection opposite

Item 11: 3/4" Superlok port connector installed into standard Swagelok® connection opposite 3/4” legacy brand nut & ferrules on Superlok fitting body

Item 12: 3/4" Superlok union elbow with one standard set of Superlok nut & ferrules and one set of legacy brand nut & ferrules

Item 13: Standard 3/4" x 1/2” legacy brand reducer mated with a Superlok union elbow and a Superlok reducing port connector

Item 14: Superlok 1/2” x 1/4" reducing port connector installed into a standard 1/2" legacy brand connection and 1/4” Swagelok® nut & ferrules on a Superlok fitting body

Item 15: Inlet Superlok 1/4” needle valve with 1/4" legacy brand nut & ferrule set

WATCH TEST 2

OUR GOAL WAS TO CREATE A SIMPLE TEST THAT WAS EASY TO OBSERVE

TEST 3: REASSEMBLY

WATCH reassmbly test

OUR GOAL WAS TO CREATE A SIMPLE TEST THAT WAS EASY TO OBSERVE

want to see more?

TELL US YOUR APPLICATION AND WE’LL CREATE & DOCUMENT A CUSTOM TEST FOR YOU

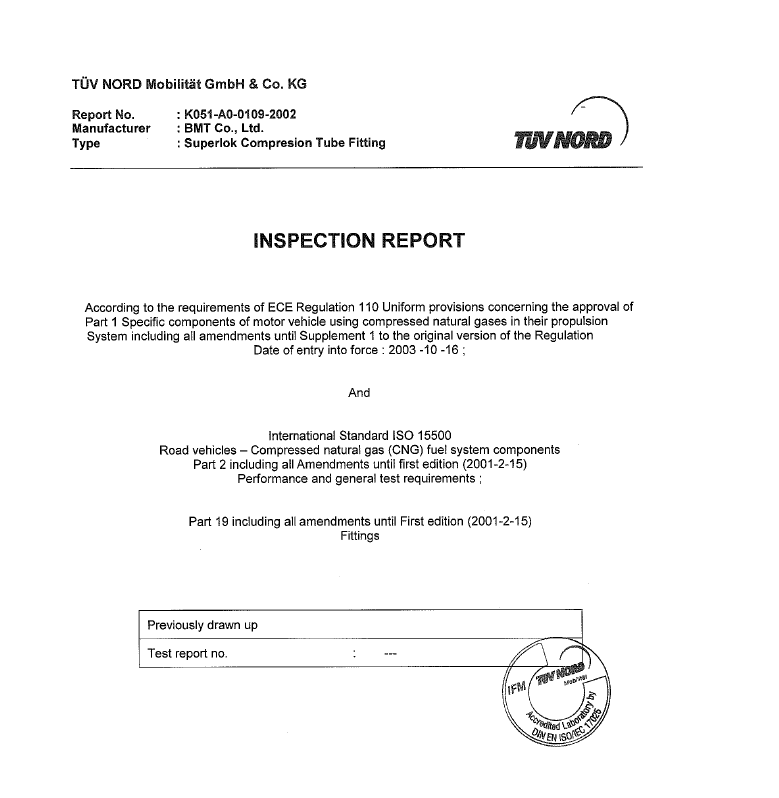

THIRD PARTY TESTING

THE DOCUMENTS SHOWN HERE ARE AVAILABLE UPON REQUEST

tube fitting TESTING: ece r110

Superlok tube fittings have been approved by 3rd party inspector TUV NORD to meet the standards of ECE R110 for use in both CNG and hydrogen powered vehicle systems. Here are some of the tests our tube fittings passed:

Over Pressure Test per ISO 15500: Test at 100 MPa (1000 bar/ 14,000psi)

Over Pressure Test per R 110: Test at 1.5 - 2x max allowable working pressure

Vibration Resistance Test: 17Hz in each of 3 orientation axes, no leakage after

O-zone Aging Test

Resistance to Dry Heat Test

Temperature Cycle Test

Corrosion Resistance Test

Excess Torque Test

CNG Compatibility Test

TUBE FITTING TESTING: ASTM F1387

ASTM F1387 is titled by ASTM as ‘Standard Specification for Performance of Piping and Tubing Mechanically Attached Fittings’, found in their section on ‘Ships and Marine Technology’. Superlok tube fittings were tested by a 3rd party and found to meet the requirements of ASTM F1387 which is considered a benchmark for high performing tube fittings throughout the industry.

LIKE TO TRY things FOR YOURSELF?

US TOO!

FREE SAMPLE fitting!

Maybe you’re like us and you’d prefer to just see something for yourself. Name a common fitting you use and we’ll send one your way along with some additional supporting material at no cost.